The Technology

Industry Preview Preliminary Planning

On this page:

Overview

Rifle and Cartridge Data

Core Machining Engine

Optimized Manual Machining Flows

CNC Tooling and Automation

Overview

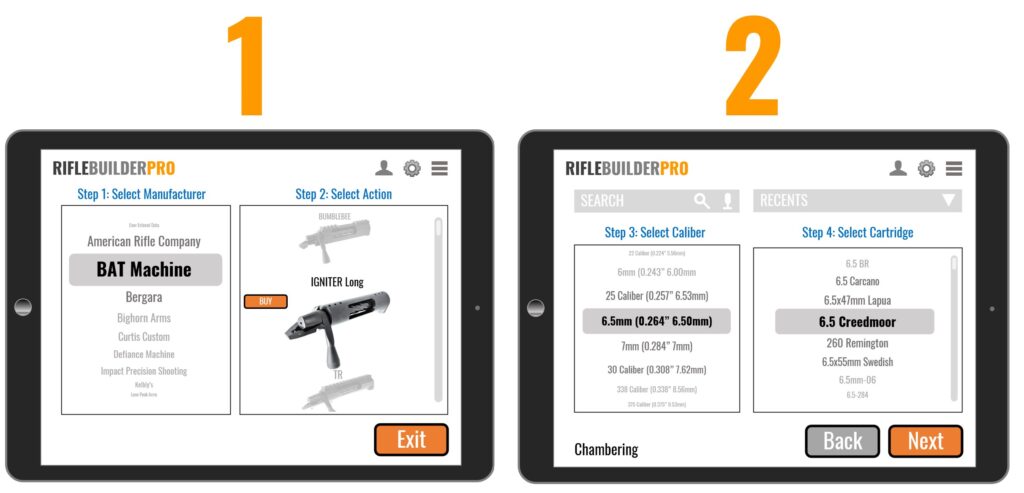

Rifle Builder PRO has made initial technology investments focused on precision rifle barrel chambering and other common machining activities like muzzle threading. For rifle barrel chambering, Rifle Builder PRO technology utilizes internal databases for both rifle actions and rifle cartridges.

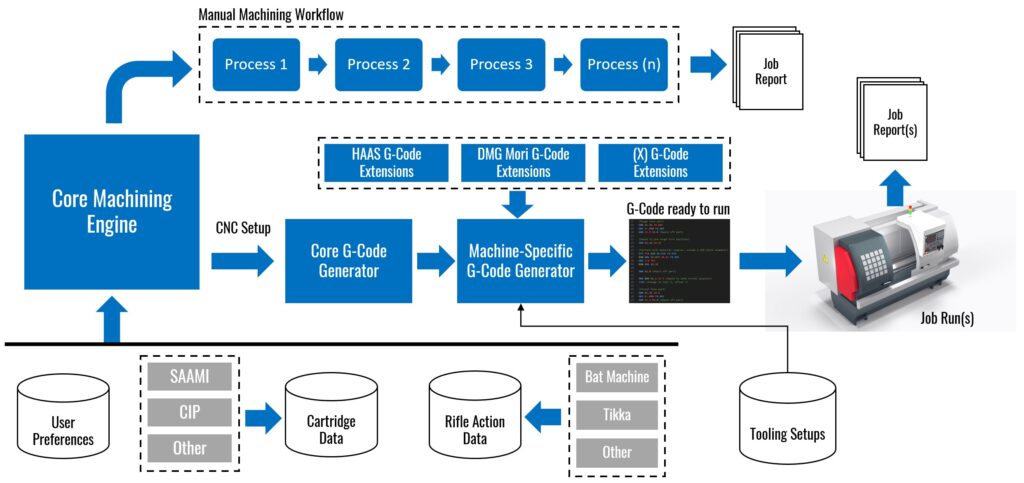

Here is a conceptual diagram outlining preliminary thinking for major software and data components:

Rifle and Cartridge Data

Rifle Builder PRO establishes common definitions and naming for the following:

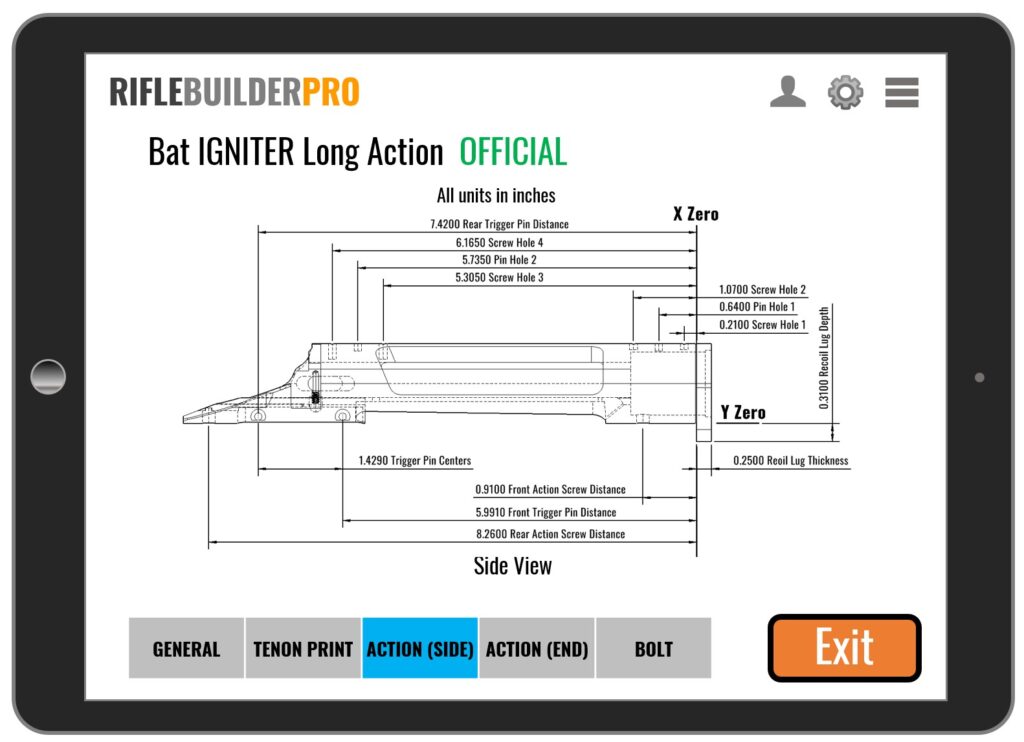

- Rifle Action Metrics: Examples include “Receiver Front to Bolt Face (headspace),” “Recoil Lug Attachment (Separate OR Integral),” “Bolt Rotation Angle,” and many more.

- Rifle Cartridge and Rifle Chamber Data: Provides standard labels to document and store cartridge data regardless of units and independent of (but in alignment with) existing standards like SAAMI and CIP. Examples include “Bolt Face Diameter,” “Bolt Face to Shoulder Start,” “Bolt Face to Shoulder Start,” and many more.

Here is a mock-up of what a portion of the Rifle Action Data could look like to the gunsmith:

Core Machining Engine

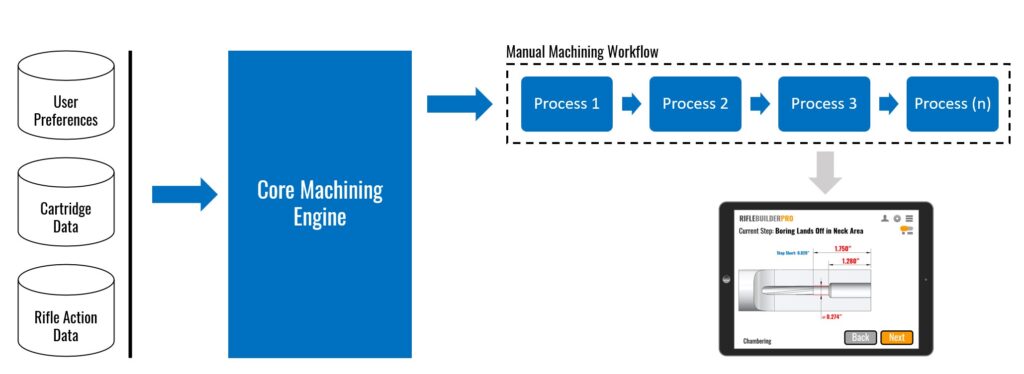

The Rifle Builder PRO Core Machining Engine takes all the required inputs, calculates all of the required parameters for a manual or CNC machining workflow, and hands that data off to the manual machining job workflow or the CNC code/control module.

An appropriate job report is stored in the cloud and can also be printed on demand.

Optimized Manual Machining Flows

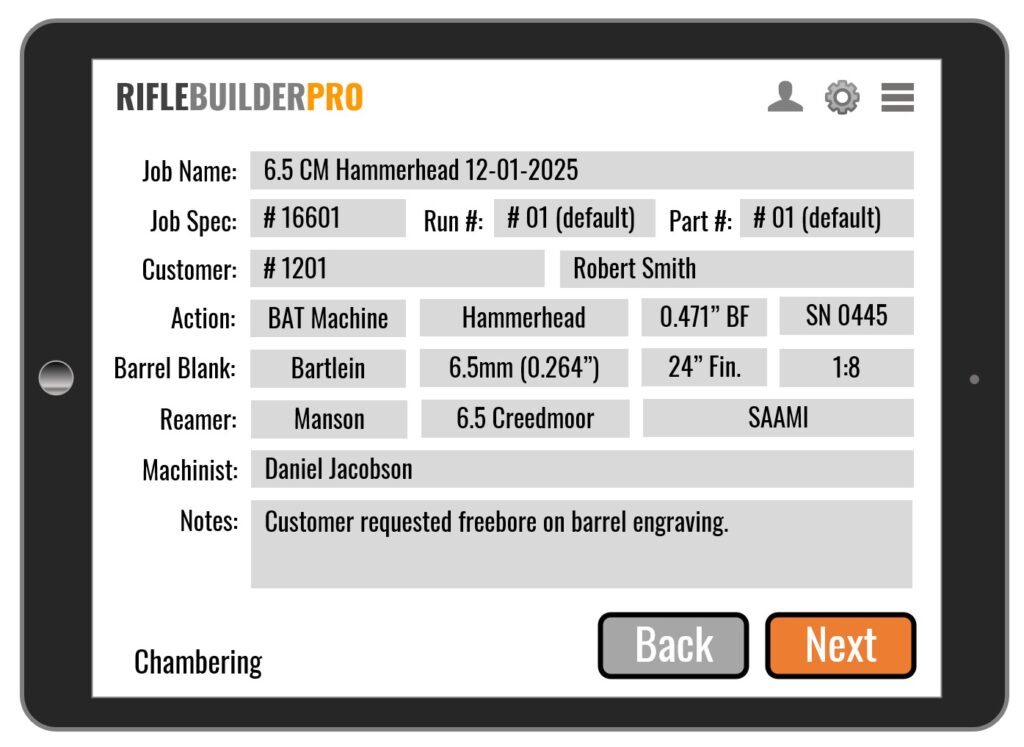

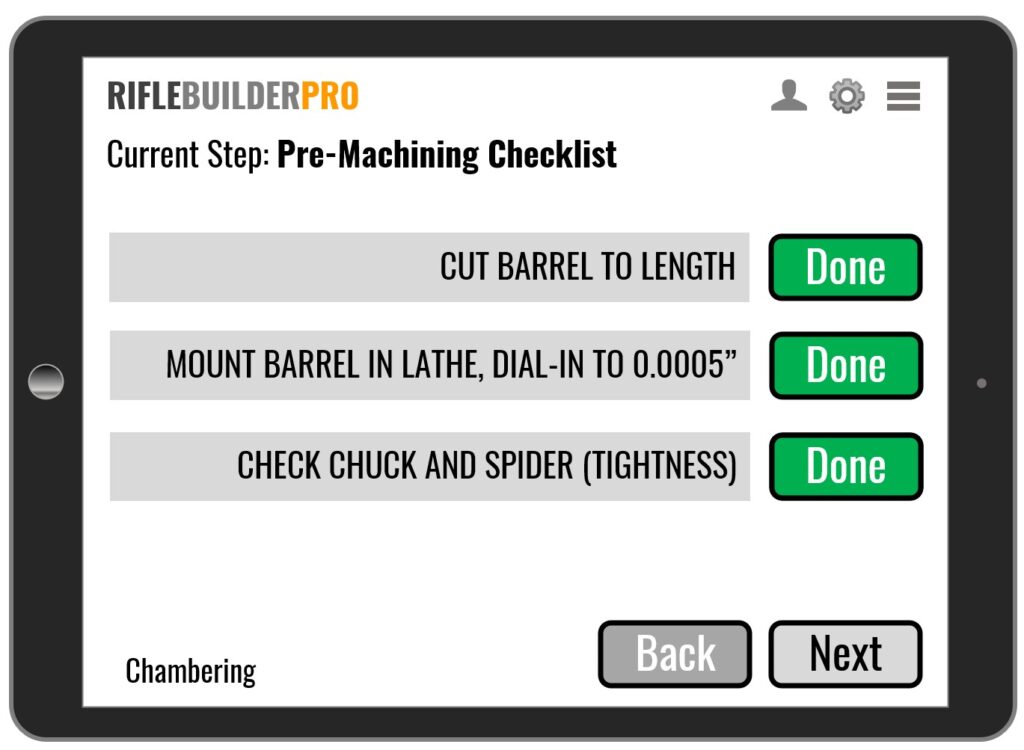

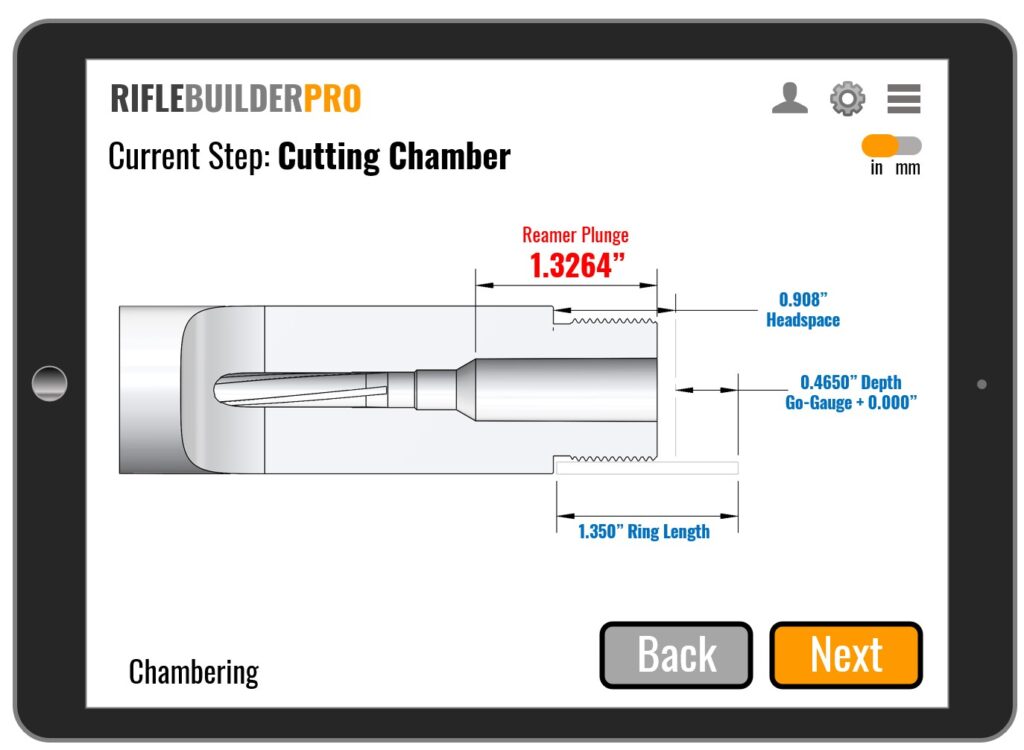

Rifle Builder PRO guides the machinist through the start-to-finish process of completing a job like barrel chambering or muzzle threading. Never before has a machinist been able to select an action and cartridge and then perform a guided and optimized machining operation. Rifle Builder PRO enables this new capability. Below is a preview of some of the experiences Rifle Builder PRO will enable.

Selecting the Action and Cartridge

Entering/Editing Job Parameters

Pre-Flight and Mid-Flight Checklists

Tailored Task-Specific Machining and Measurement Activity Pages

Seamless Traversal Between Units Systems

CNC Tooling and Automation

Rifle Builder PRO will support end-to-end CNC machining, measurement/checks, and job reports as a part of future releases. Research, development, and testing are already underway.

Some of the planned features include:

- Standardized Tooling Setups: cutting tools, turret positions with multiple tools/offsets and corresponding conventions for offsets, etc.

- Interactive models for setup, machining checks, and inspection

- Direct support for arbitrary rifle actions and cartridges without special programming

- Training for CNC operators in how to set up for and use Rifle Builder PRO (sold separately)